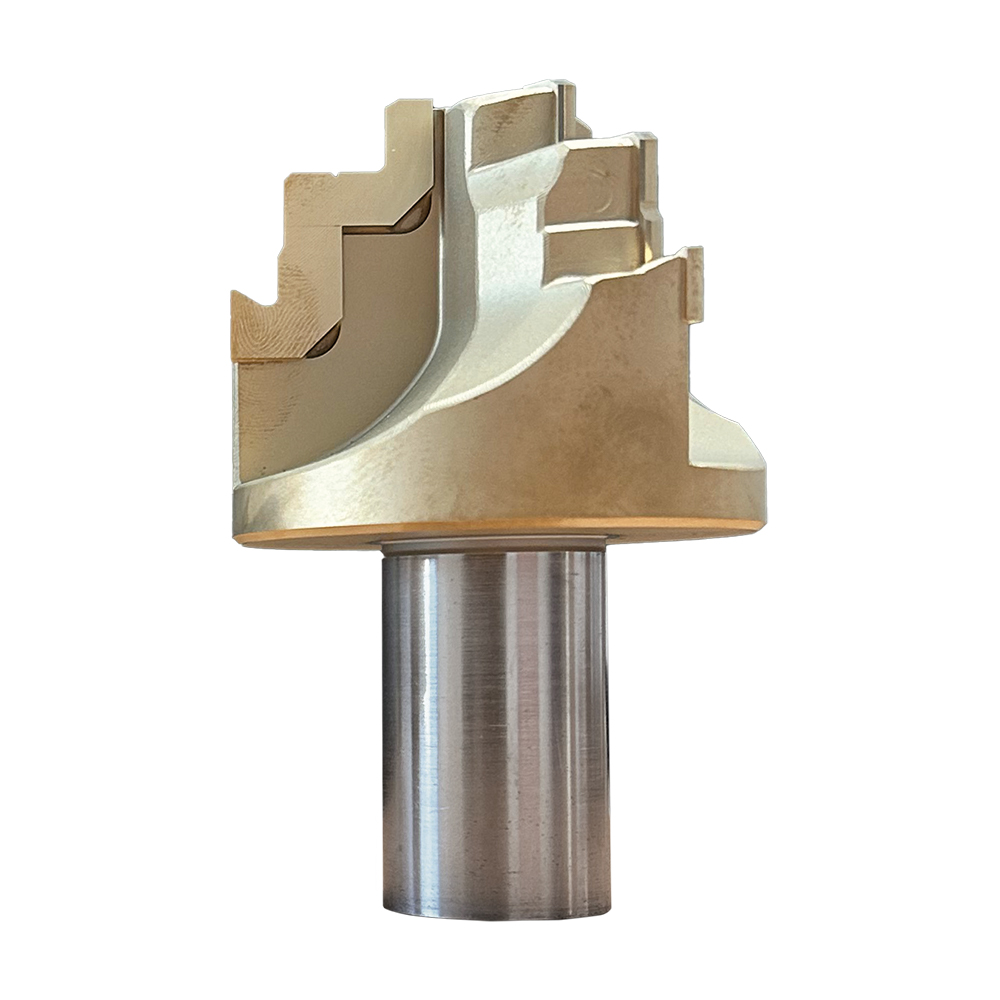

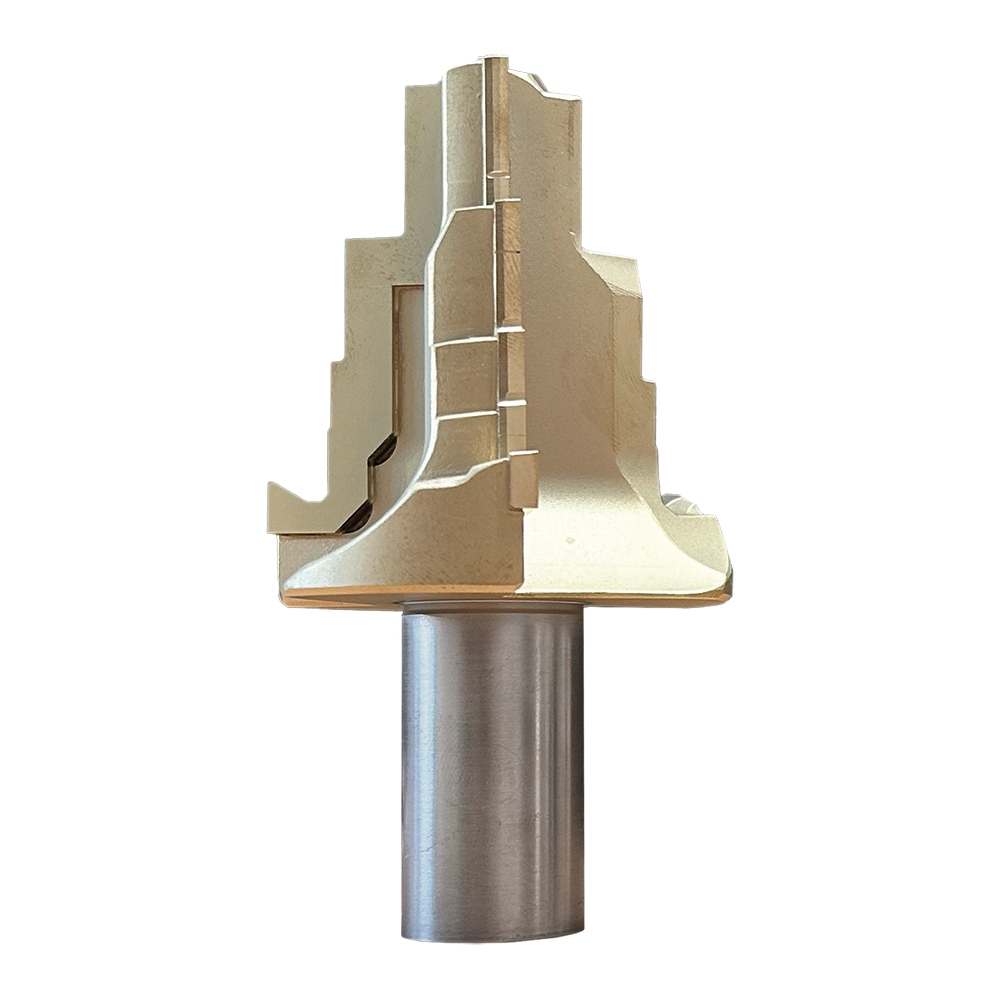

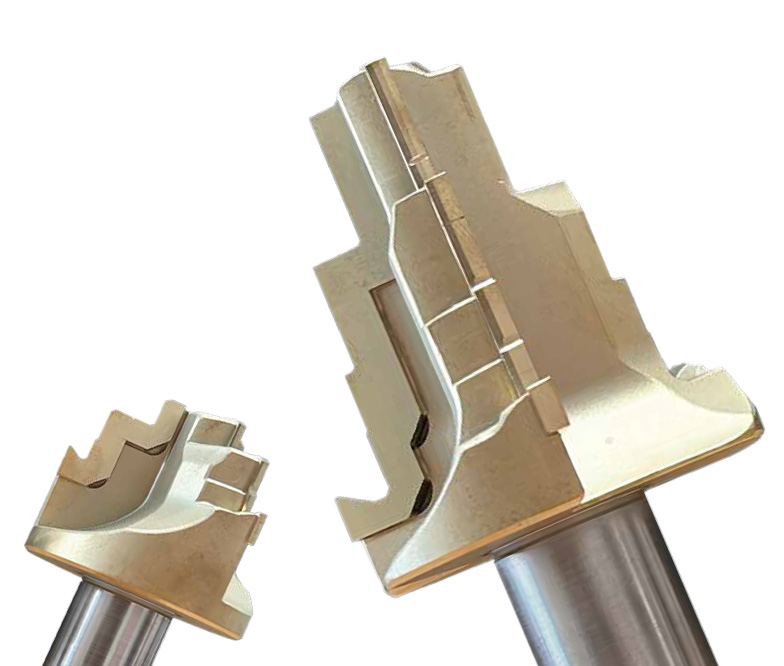

Modular multilayer coating with AAI (High Ionization Arc) technology with a Titanium and Niobium-based composition

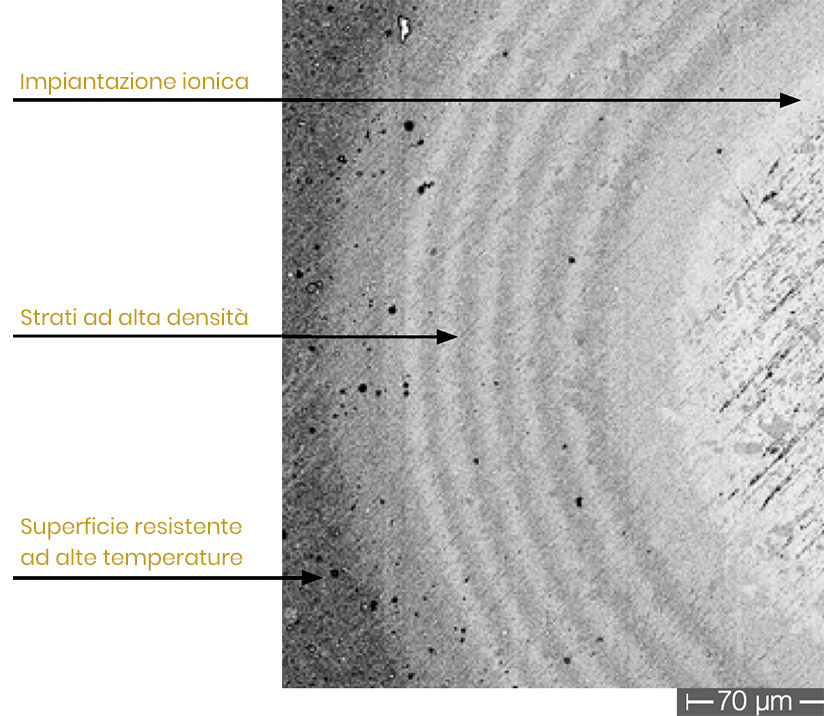

The HELIOS coating, based on Titanium Niobium Nitride, has a high-density nanocomposite structure.

It achieves extreme chemical and thermal inertness through progressive and controlled adjustment of the coating density.

The coating can be adjusted for different applications based on the deposition temperature, varying between 250° and 600°C, and thanks to the modulation of different preparation and plasma finishing steps.

Technical features of the coating

| Coating colour | Hardness | Elastic modulus E | Oxidation temp. | Coeff. of friction on 100Cr6 | Deposition temp. | Typical thickness |

|---|---|---|---|---|---|---|

| Light yellow | 2700 ± 50 HV | 380 ± 10 GPa | >1800°C | 0,30 | 250°C - 600°C | 1-2 µm |