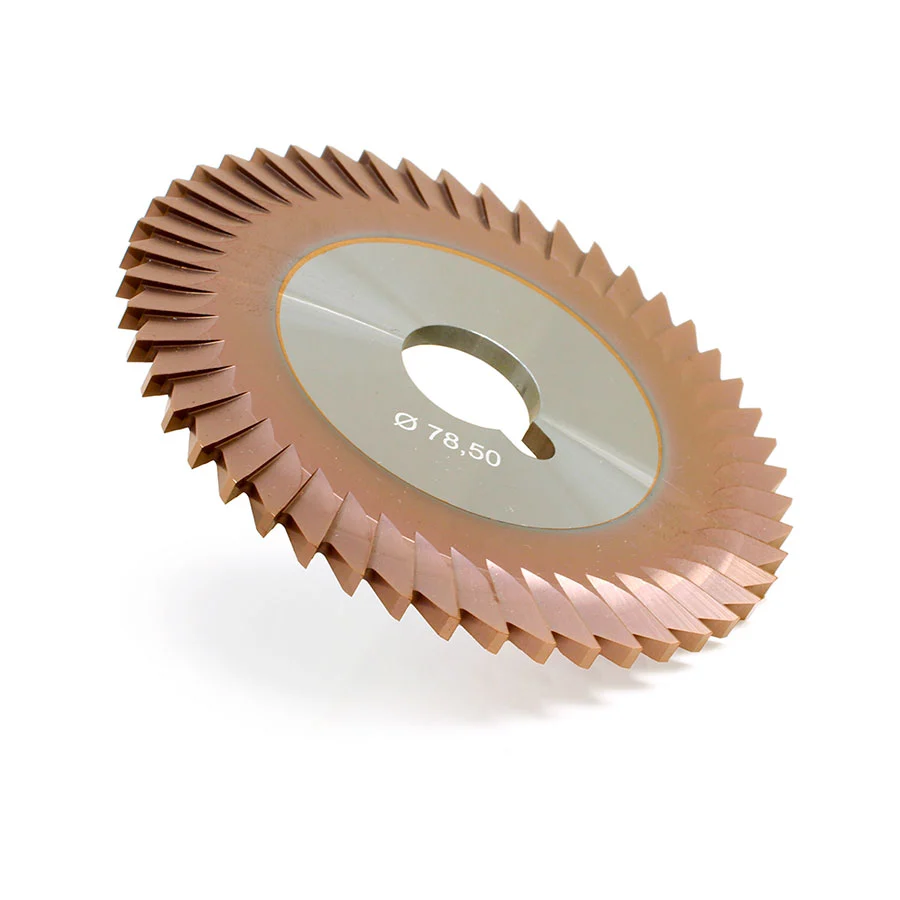

Multilayer coating, composed of aluminum, chromium, titanium, and silicon for the most extreme machining operations

The SiliCrome coating is a multilayer of aluminum, chromium, titanium, and silicon, where the different layers are designed to optimize hardness and toughness.

The alternating layers allows for modulation of the mechanical and wear-resistant properties of each individual layer.

Thanks to the microcrack arrest mechanism at the interface between the individual layers, tool life is extended.

The reduced thickness of the coating perfectly conforms to the morphology of the cutting edge, preserving its sharpness. The process produces a smooth, sliding surface. The treatment promotes the passivation of the coating and makes it suitable for high operating temperatures.

Technical features of the coating

| Coating colour | Hardness | Elastic modulus E | Oxidation temp. | Coeff. of friction on 100Cr6 | Deposition temp. | Typical thickness |

|---|---|---|---|---|---|---|

| Purple orange | 4000 ± 50 HV | 560 ± 10 GPa | >1100°C | 0,35 | 480° C | 2-4 µm |