Quality Control

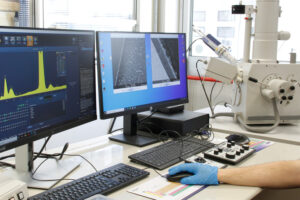

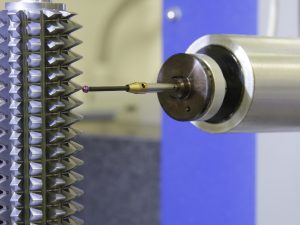

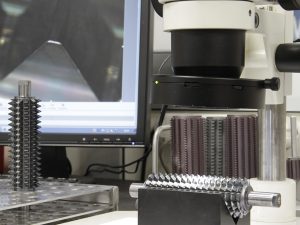

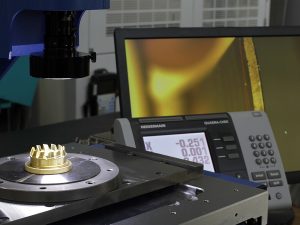

The Quality Control department verifies the dimensional and functional conformity of gear tools at all stages of the production process.

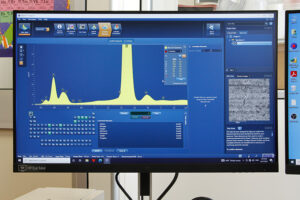

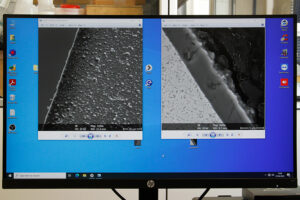

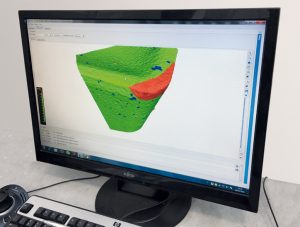

Using high-precision measuring systems, including the Alicona Edge Master 3D optical microscope, it performs advanced metrological checks on profiles, cutting radii, angles, and surface roughness.

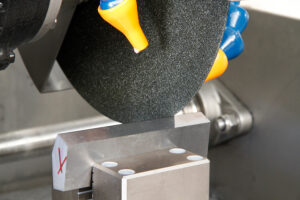

PVD coating analyses (thickness, adhesion, and uniformity) ensure compliance with required tolerances and design specifications, ensuring process repeatability, production stability, and high finished product performance.

Technology and Quality

The quality of our work is controlled thanks to specific instruments for the analysis of the surfaces and the cutting edges of the chip removal tools.

Coating thickness and adhesion are constantly monitored. Our technical staff is highly qualified and able to constantly monitor, optimize and develop our range of treatments.

The service we offer

miniToolsCoating has always stood out for its quick, precise and reliable coating service, always meeting the customer's needs.

Quality control department

- 1 MDM involute tester

- 1 Alicona Edge Master

- 1 metallographic microscope

- 1 Zoller Power Vision

- 1 stereomicroscope

- Calo test

- HRC hardness tester

- Roughness tester