PVD coatings for hot stamping

Our experience at the service of the customer

Thanks to our continuous search for innovative solutions, we have developed and offer a range of PVD coatings specifically for hot stamping, improving the life and performance of our tools.

Reliability, precision, and quality are our core values.

TECHNOLOGY AND SUPPORT

To remain a benchmark in the global market and ensure ever-better support for our customers, we have adopted the best technologies for process control and management, as well as the most advanced deposition systems.

We continually invest in new facilities, cutting-edge machinery, and technological updates, while also ensuring ongoing technical and scientific training for our staff to offer increasingly efficient and reliable solutions.

DEDICATED TECHNICAL SUPPORT

To offer tailored support, our technicians can conduct on-site inspections. This allows us to identify any critical process issues and find the best solution for your needs through on-site analysis and measurements.

Thanks to direct contact with our technical staff, we guarantee a personalized service, designed to solve specific problems and optimize performance.

Our PVD coatings for hot stamping

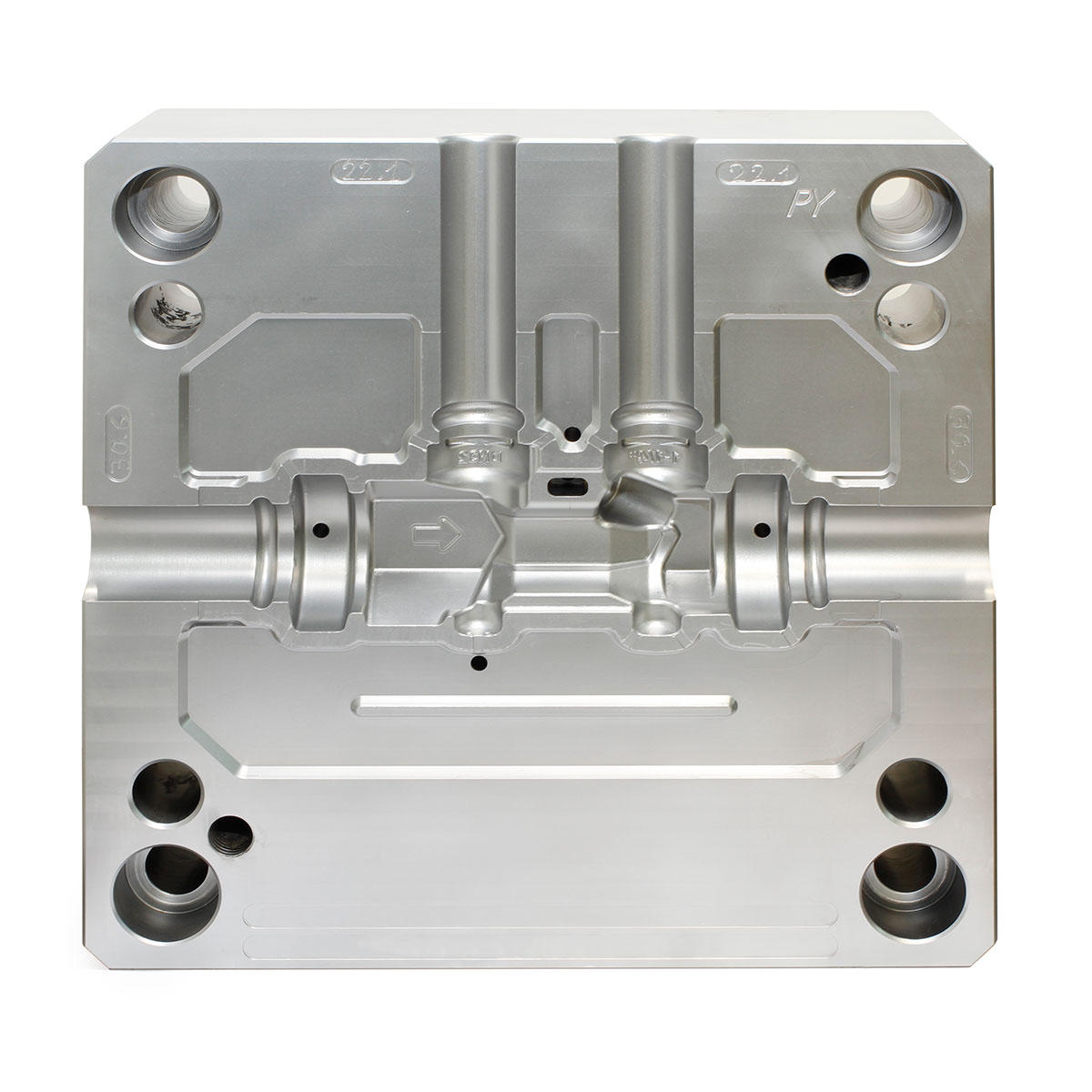

Alticrome

This is an innovative coating perfectly combining the properties of its component elements: Aluminium, Titanium and Chromium.

It has a high oxidation temperature and, thanks to its nanolayer structure, it has a very high resistance to corrosive wear. Moreover, it has an excellent anti-adhesive power and a low coefficient of friction.

When to use the Alticrome coating

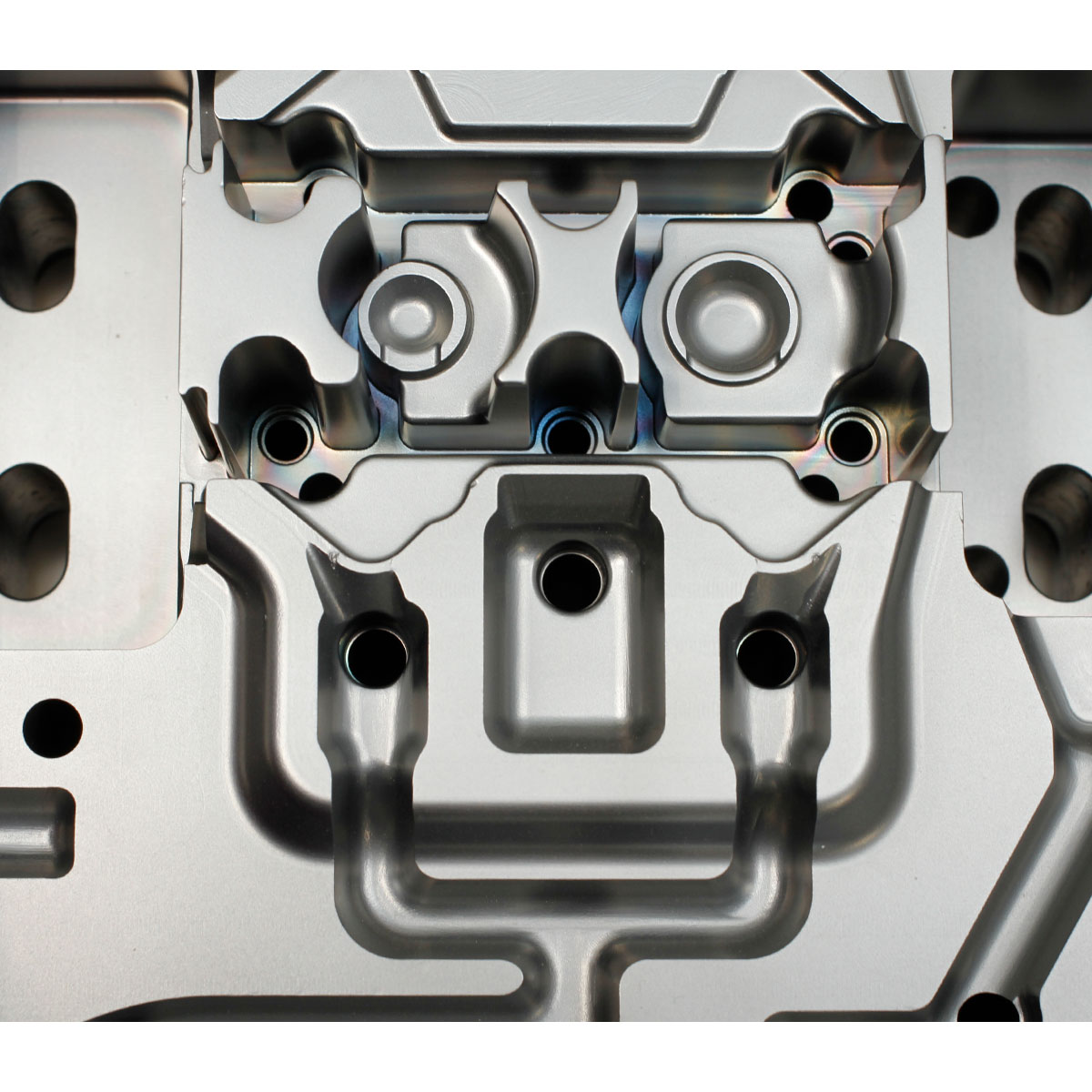

- ALUMINIUM AND ZAMAK DIE CASTING DIES

- SHEARING AND FORMING DIES

- PLASTIC MOULDS

NiCOAT

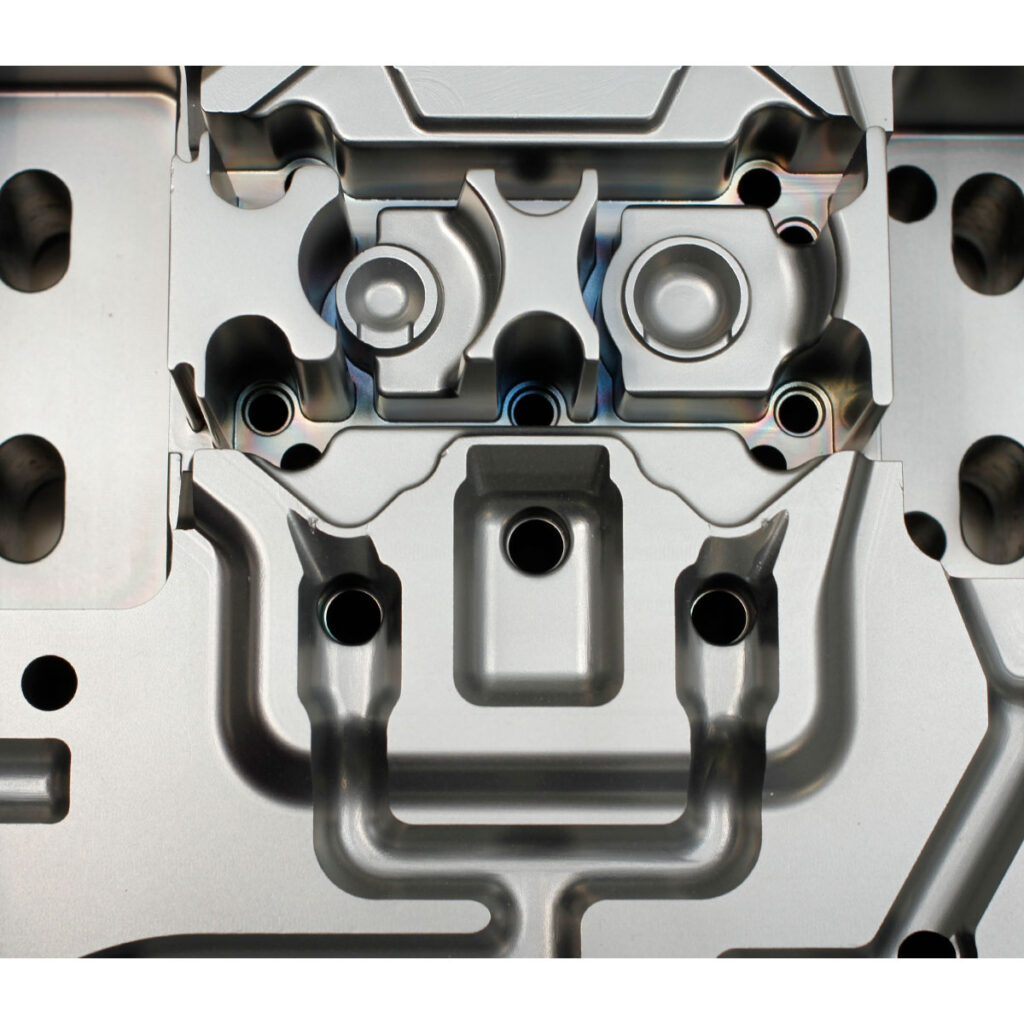

This innovative coating is the result of a synergy between plasma nitriding and state-of-the-art PVD coating; the two steps are executed during the same cycle to avoid the formation of a white layer which typically constitutes a problem for the adhesion of any PVD coating and must normally be removed by microblasting and/or further polishing.

When to use the NICOAT coating

- ALUMINIUM AND ZAMAK DIE CASTING DIES AND COMPONENTS

- HOT DIE CASTING AND COLD DIE CASTING OF STAINLESS AND HIGH STRENGTH STEELS

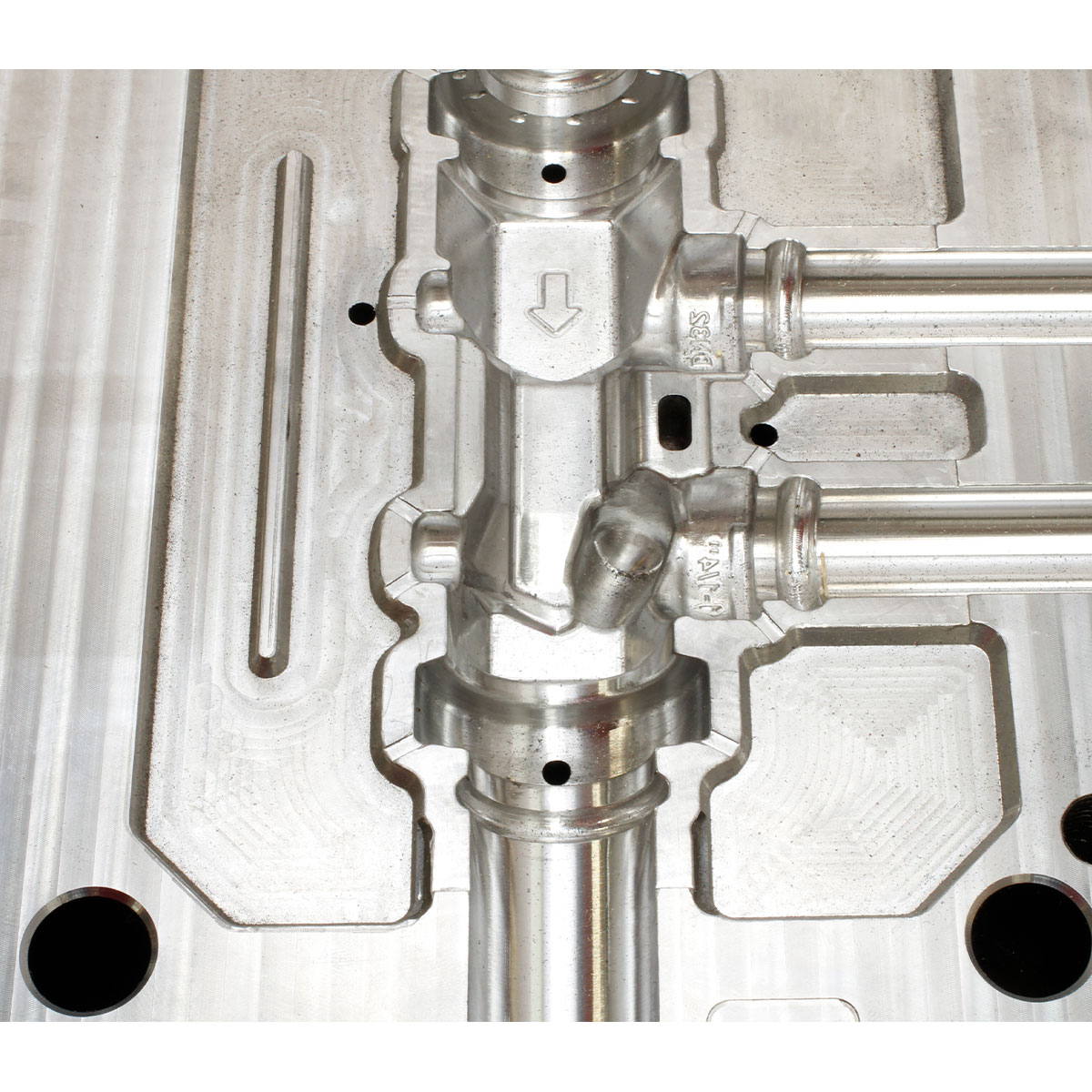

PVD Coating for Hot Forging

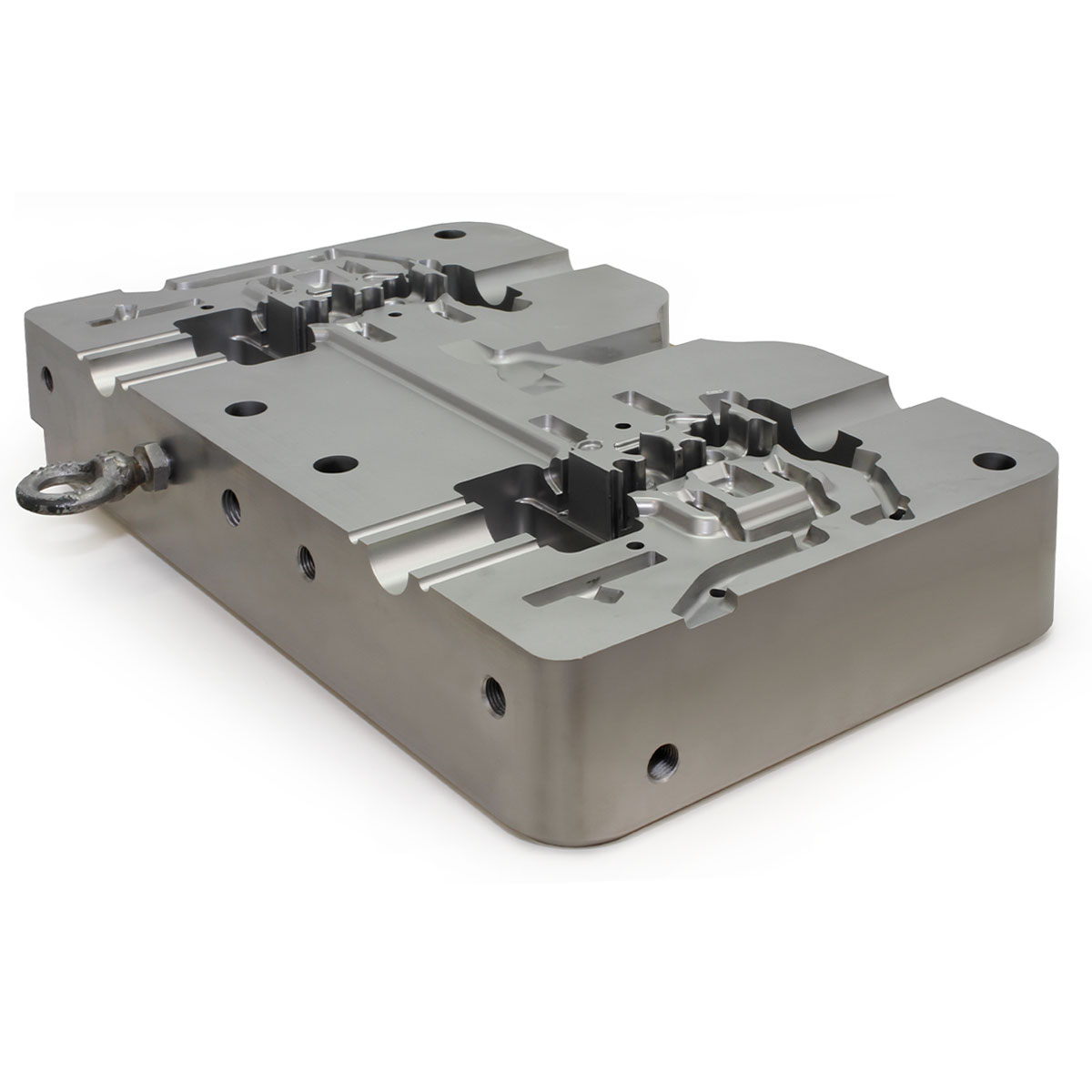

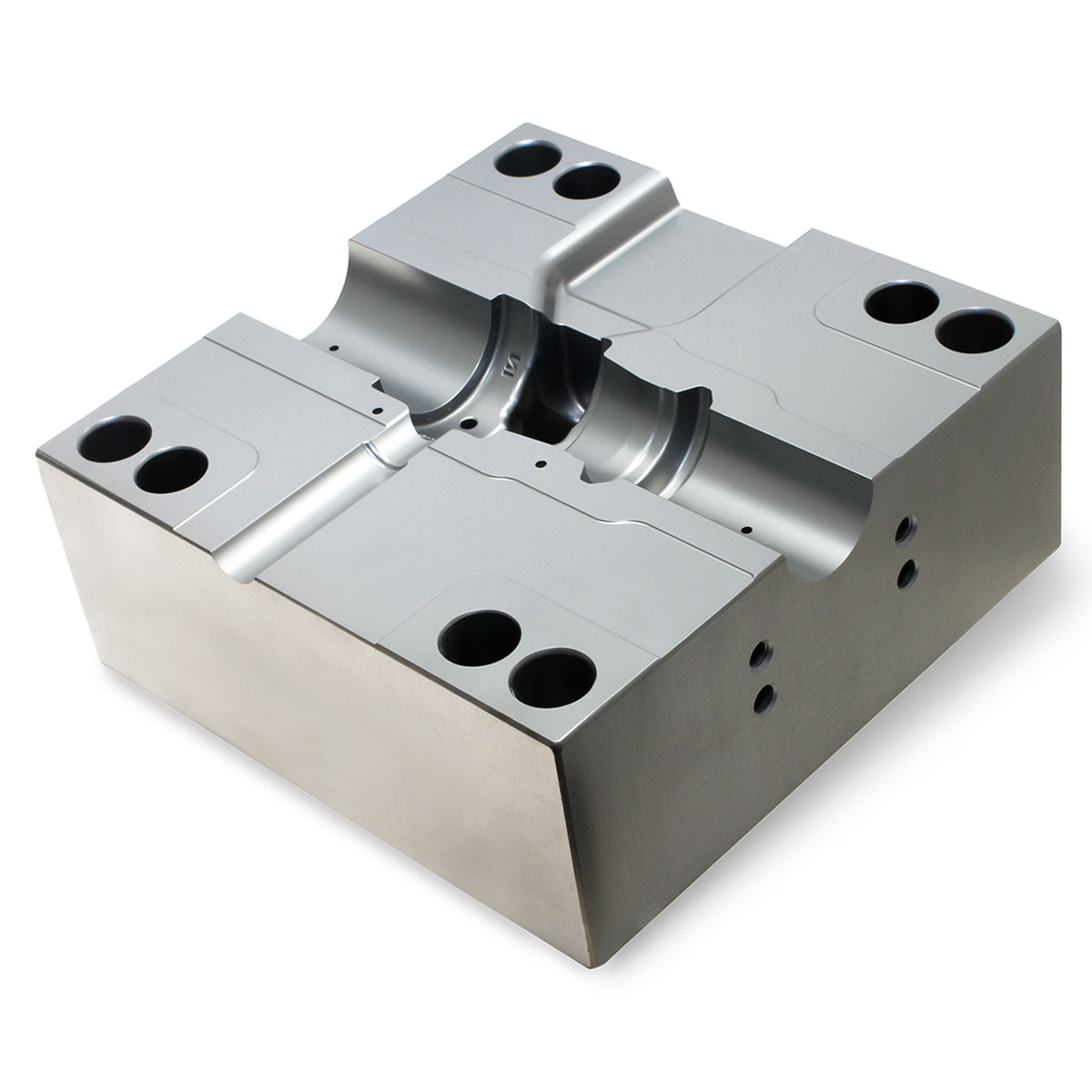

PVD coating for hot forging is an advanced solution for improving the performance of tools and molds used in high-temperature and compression processes, such as in the production of valves, plumbing, heating, and refrigeration systems.

Thanks to its high hardness and thermal resistance, PVD coating reduces maintenance, increases the life of tools and molds, and lowers production costs, ensuring greater efficiency and reducing machine downtime.

Various coatings have been designed and optimized for different materials, such as brass, steel, aluminum, and copper.

High ionization PVD technology

miniTools Coating uses High Ionization Arc PVD technology, which allows the coating to be deposited atom by atom in the form of charged particles.

This innovative technology ensures greater penetration even in the most complex geometries. Furthermore, it offers the highest structural density compared to other PVD technologies available on the market, minimizing droplet formation, a typical defect of traditional cathodic arc technology.