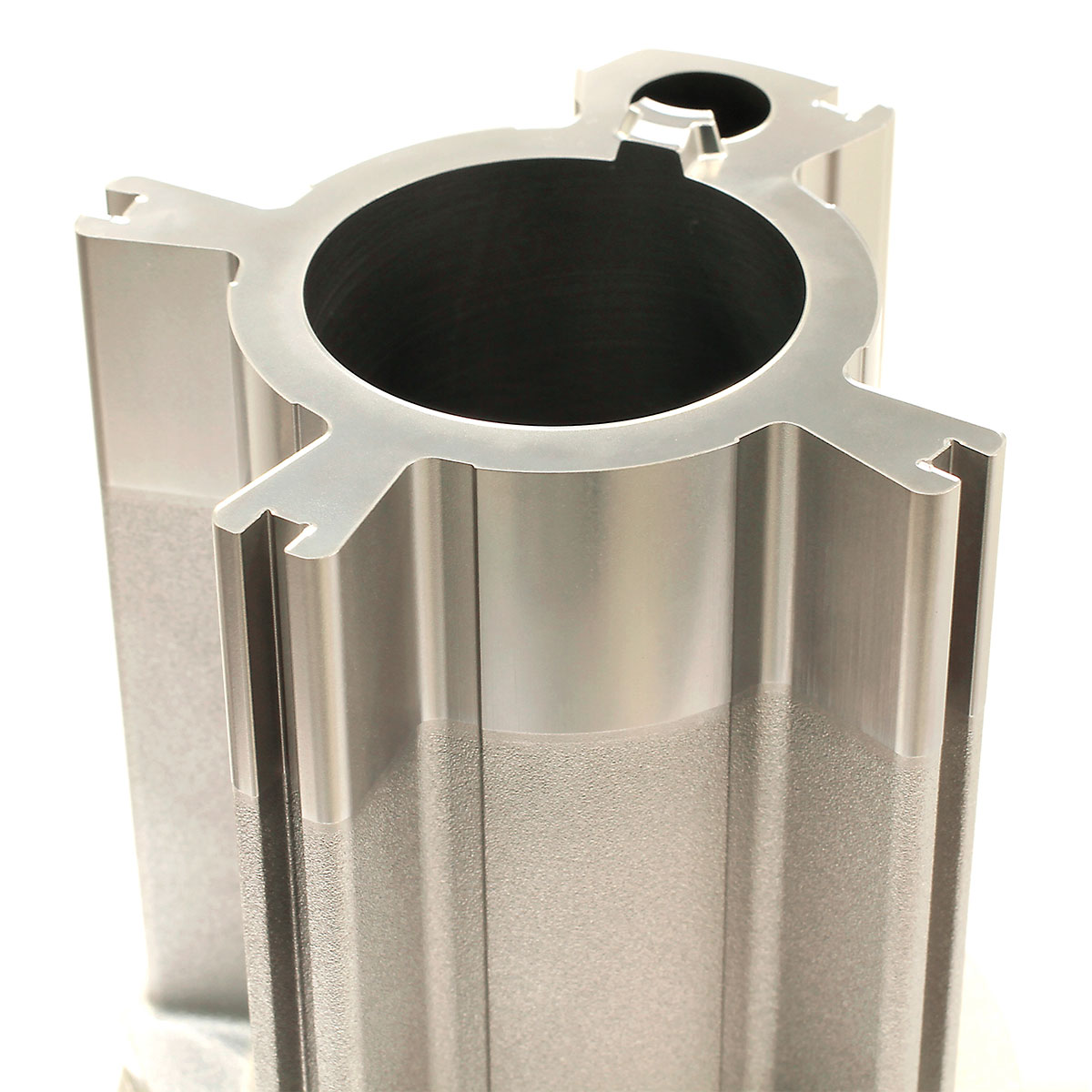

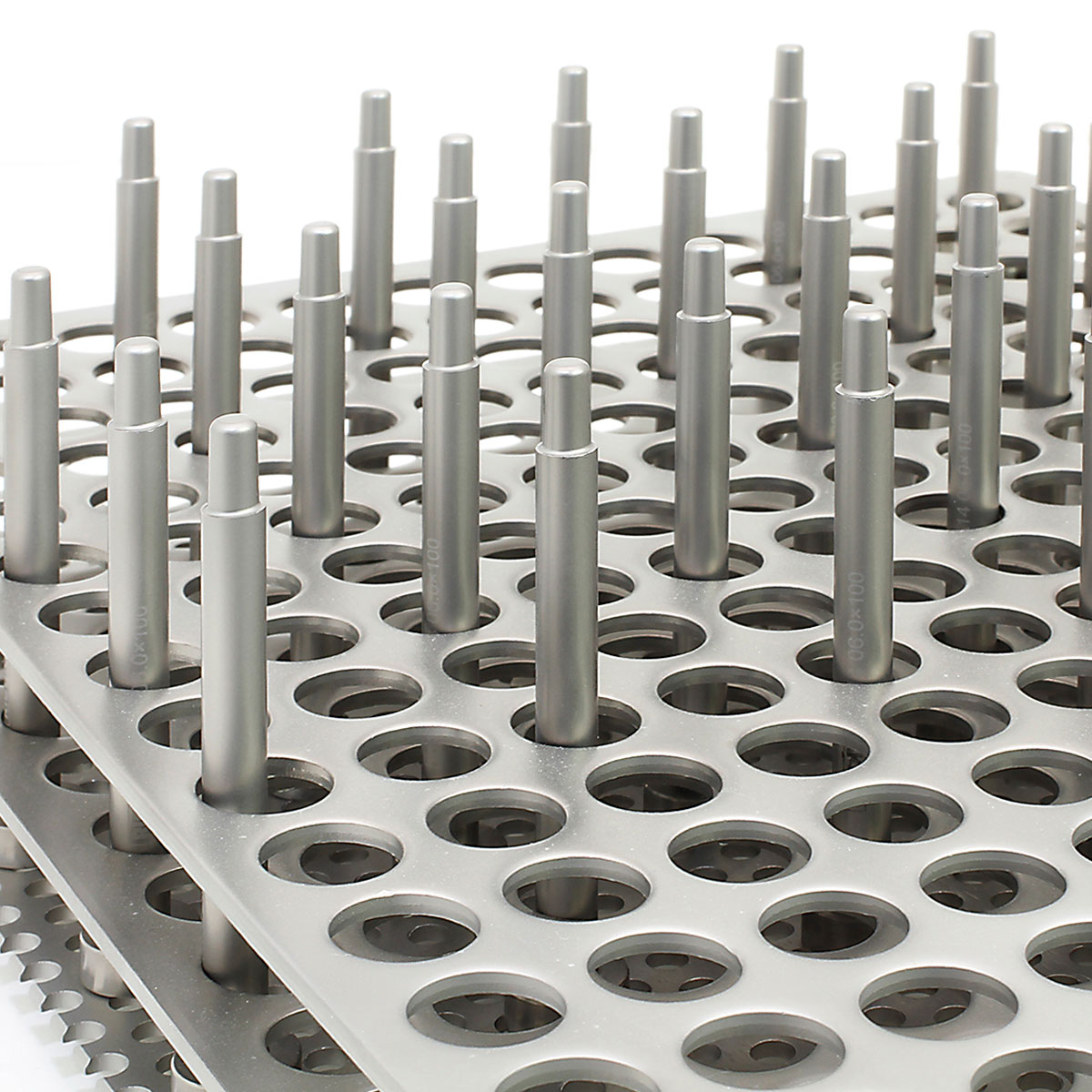

Cold pressing

Sheet metal stamping and blanking benefits significantly from the application of PVD coatings to the tools used.

For optimal results, the coatings applied must have special surface characteristics, must withstand very high compression cycles, and must have particularly low roughness to achieve a low friction coefficient.

To prevent cold welding or galling of the material being worked, the specific chemical formulation of the coating must also be considered, based on its chemical affinity with the material being worked.

We offer TiN and TiCN coatings for cold forming, always in dedicated fillers.

For bending and blanking operations on high-alloy steels, we recommend Alcro-X coating. For coining and forming operations, the recommended coating is Alticrome, which, thanks to the presence of chromium, facilitates the flow of the materials it comes into contact with.

Where particularly high abrasion rates need to be counteracted, NICOAT coating (preceded by a plasma ion nitriding phase) represents the pinnacle of miniTools Coating's cold forming technology.